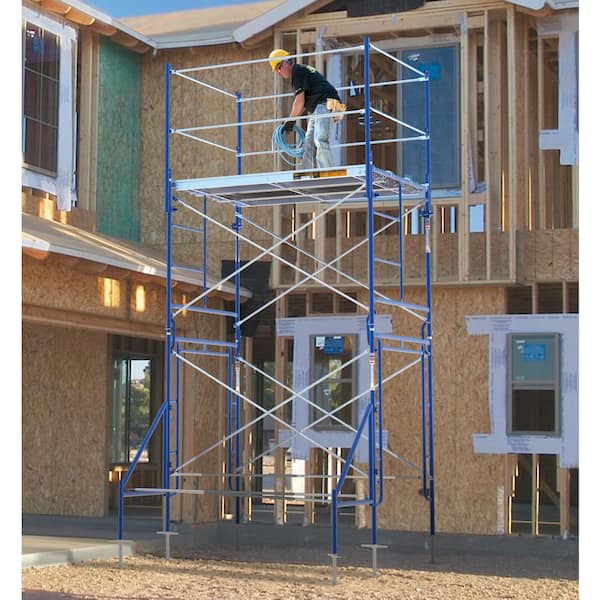

7′ x 5′ x 5′ Steel Mason Scaffolding Tower Set

Related Products

- Description

- Additional information

Description

Overview and Specifications of the 1-Story Steel Mason Scaffolding Tower

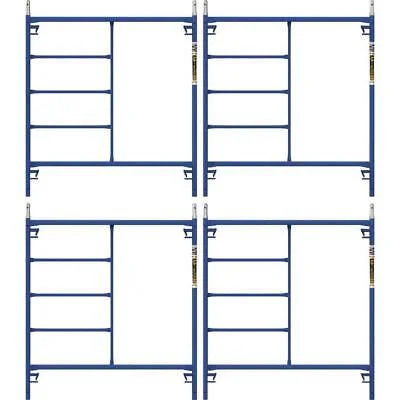

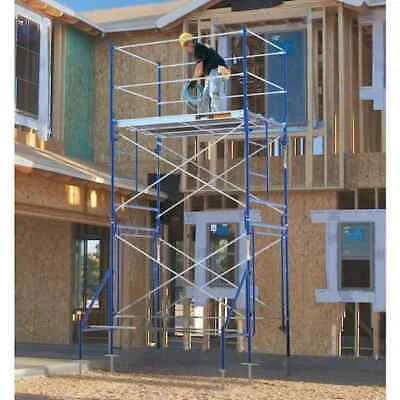

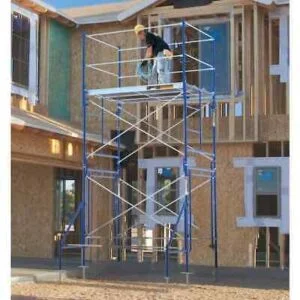

The 7′ x 5′ x 5′ 1-story steel mason scaffolding tower set system epitomizes robust construction and functionality. Designed with precision, this scaffolding tower measures 7 feet in length, 5 feet in width, and 5 feet in height, making it a versatile solution for a variety of construction needs. The substantial use of high-grade steel ensures unparalleled durability and reliability, adept at supporting significant weight loads essential for safety on the job site.

A key feature of this scaffolding tower is its weight capacity, as it can support a maximum load of up to 1,000 pounds. This capacity ensures that multiple workers can operate safely on the platform simultaneously, along with their tools and materials. The structural integrity of the tower is bolstered by its cross braces, which provide additional stability and minimize sway, a critical aspect for maintaining safety standards in demanding work environments.

To combat the rigors of outdoor use, the steel components are treated with specialized anti-rust coatings. These coatings prevent corrosion, significantly extending the lifespan of the scaffolding set and maintaining its structural integrity. This anti-rust feature is particularly beneficial in harsh weather conditions, where exposure to moisture typically accelerates wear and tear.

Safety is further enhanced through several design elements such as guardrails and non-slip surfaces on the platforms. These features are instrumental in minimizing the risk of falls and other accidents, ensuring a secure working environment. The scaffolding tower is also designed for ease of assembly. Its modular components allow for quick setup and disassembly, saving valuable time and effort on the part of the construction team.

The 1-story steel mason scaffolding tower is perfect for a variety of projects, notably those involving masonry, painting, or façade work. For instance, it is ideal for bricklaying tasks, as the robust platform withstands the constant movement and weight of bricks and mortar. Similarly, painters benefit from the wide, stable workspace that reduces the need for frequent repositioning. Additionally, it is well-suited for tasks such as window installation and exterior maintenance, providing a stable and secure platform for workers at convenient heights.

Benefits and Usage Tips for the Scaffolding Tower with Cross Braces

The 7′ x 5′ x 5′ steel mason scaffolding tower set system is renowned for its robust structure and reliable performance, particularly thanks to the inclusion of cross braces. These cross braces play a pivotal role in enhancing the overall stability of the scaffolding tower, ensuring that it remains steady and secure even when subjected to heavy loads or adverse weather conditions. The cross braces counteract lateral forces, preventing any potential wobbling or tipping, which significantly reduces the risk of accidents, thereby making the scaffolding ideal for a myriad of construction and masonry tasks.

To fully harness the benefits of this scaffolding system, it is crucial to follow best practices for assembling and disassembling the structure. Firstly, always ensure that the ground or surface on which the scaffolding is to be erected is level and firm. During assembly, methodically attach the cross braces, ensuring that each connection is tight and secure. This meticulous attention to detail during setup not only enhances the stability but also extends the longevity of the scaffolding system. Disassembling should be carried out with similar precision, paying attention to disengage all cross braces gently to prevent any damage or undue stress on the components.

Maintaining the scaffolding tower is equally important to ensure its durability and reliable performance. Regular inspections should be conducted to identify any wear and tear, with particular focus on the cross braces and joint areas. Cleaning off any accumulated debris and checking for rust can prevent potential weakening of the structure. Proper storage in a dry, covered area also helps in preserving the integrity of the scaffolding system.

Safety precautions are paramount when using the scaffolding. Always employ safety gear, such as harnesses and helmets, especially when working at higher elevations. Additionally, it is advisable to avoid overloading the scaffold beyond its recommended capacity and to ensure that all users are aware of the proper safety protocols. Expert advice often suggests having a safety net or guardrails installed around the working platform to provide an extra layer of protection.

Many users and experts have lauded the 7′ x 5′ x 5′ steel mason scaffolding for its ease of use and reliability. One user noted how the cross braces provided unmatched stability during a significant masonry project, allowing for seamless and safe operation. Such testimonials underscore the scaffolding’s suitability for demanding construction environments, establishing it as an indispensable tool for professionals seeking quality and safety in their projects.

Saferstack 7 ft. x 5 ft. x 5 ft. 1-Story Steel Mason Scaffolding Tower Set System with Cross Braces, 9920 lbs. Capacity

Product Description

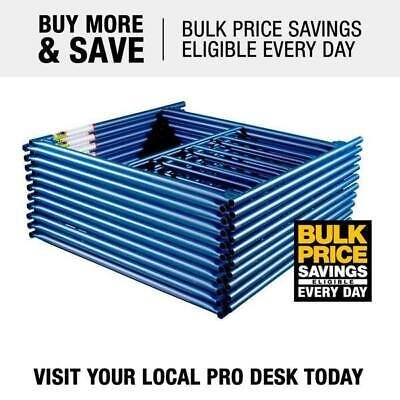

This MetalTech Saferstack Scaffold Set helps you reach higher and wider with the ability to connect multiple scaffold sets. This set includes two 7 ft. by 4 ft. cross braces and it stacks in 30-percent less space than regular frames. The Saferstack frames interlock for safer transport and storage, so its extra secure. It’s also highly durable and weather-resistant with a textured, anti-slip powder-coat finish.

Our other same products Click

Our other hotselling products on youtube

Additional information

| Size | no-size |

|---|---|

| note | |

| mpn | |

| Model | does-not-apply |

| Brand | metaltech |